Tanja Schötz, Quality Control

We rely on fast

analysis methods.

Our rapid analysis methods are three to four times faster than those of other providers.

Tanja Schötz, Quality Control

Each team has 10 to 14 lab technicians

and adheres to current GMP guidelines.

We inspect all materials

purchased from suppliers.

We check each individual step.

Approving the finished API is

part of our quality

control process.

Numerous, comprehensive

stability studies set us

apart from the rest

of the field.

We transfer our customers’

methods to our laboratories,

validate them and then use

them – providing all services

from a single source.

Our rapid analysis methods are three to four times faster than those of other providers.

Tanja Schötz, Quality Control

For instance, we need just two to three minutes for in-process measurements with UPLC. We’re also pretty speedy at gas chromatography, which only takes seven minutes. To put this into perspective, older methods required 35 minutes to produce a comparable analysis.

Sebastian Troidl, Quality Control

We have no trouble keeping up with international competitors. We approve 4900 batches a year, with over 7000 samples.

analytical instruments ourselves and train our employees accordingly.

are chemists, chemical engineers and 40 laboratory technicians.

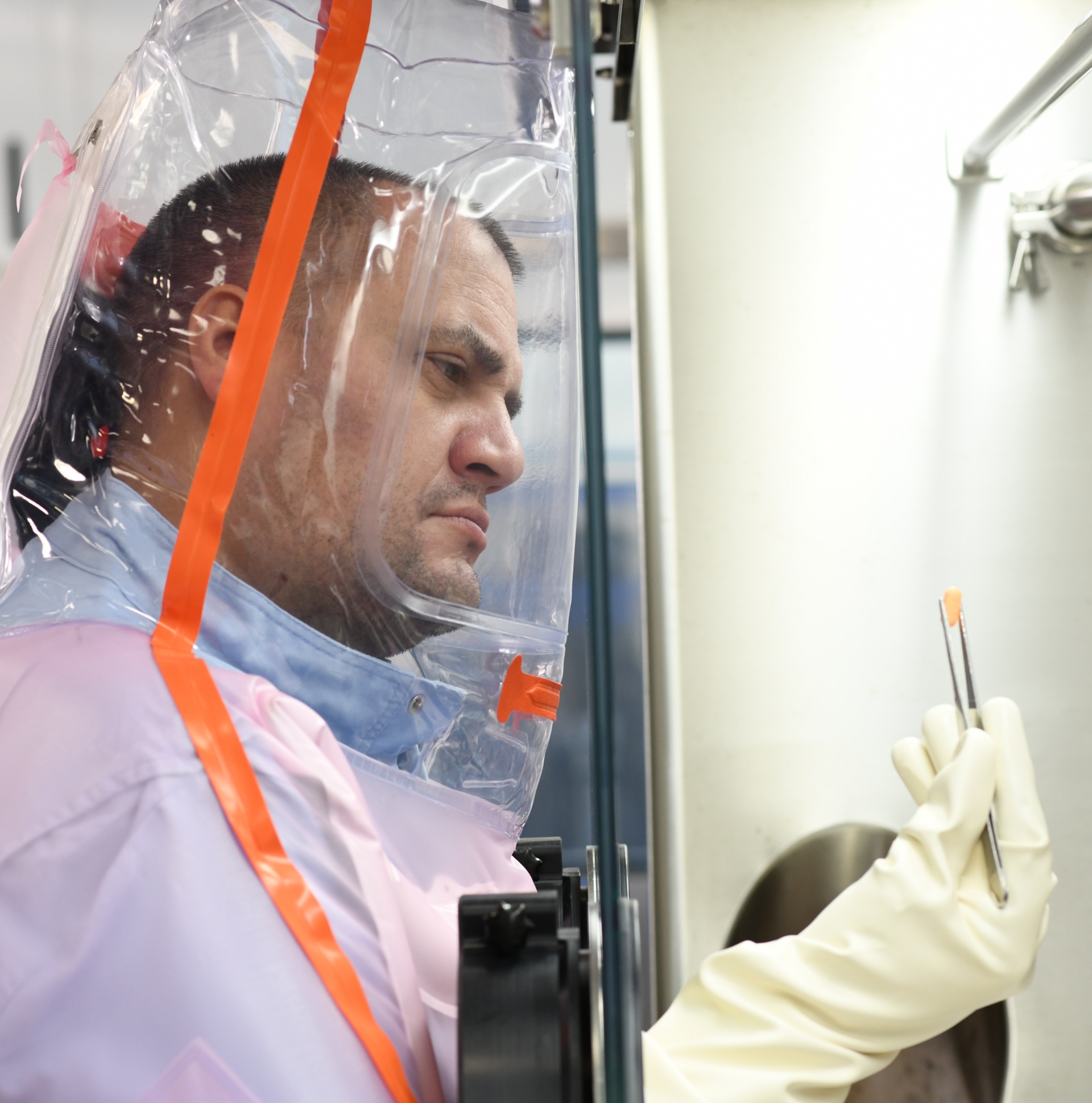

PRODUCING ACTIVE PHARMACEUTICAL INGREDIENTS

We produce highly potent active pharmaceutical ingredients – from

5 kg to 20 tons.

DEVELOPMENT OF TABLETS AND CAPSULES IN THE HIGH POTENT RANGE

We develop and manufacture products in line with international standards.

ENVIRONMENTAL PROTECTION, OCCUPATIONAL SAFETY AND HEALTH

This is how we protect our colleagues and our environment.