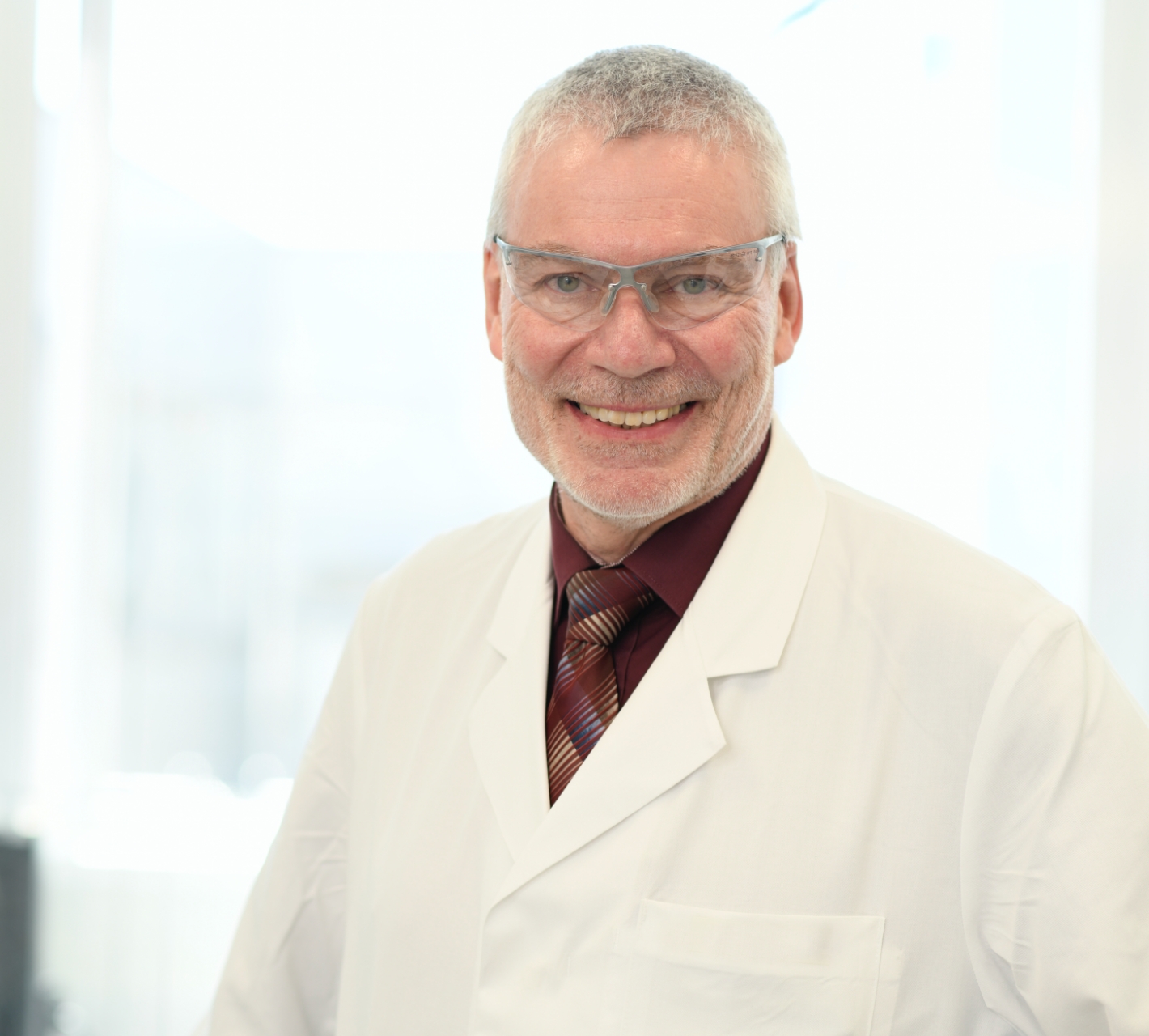

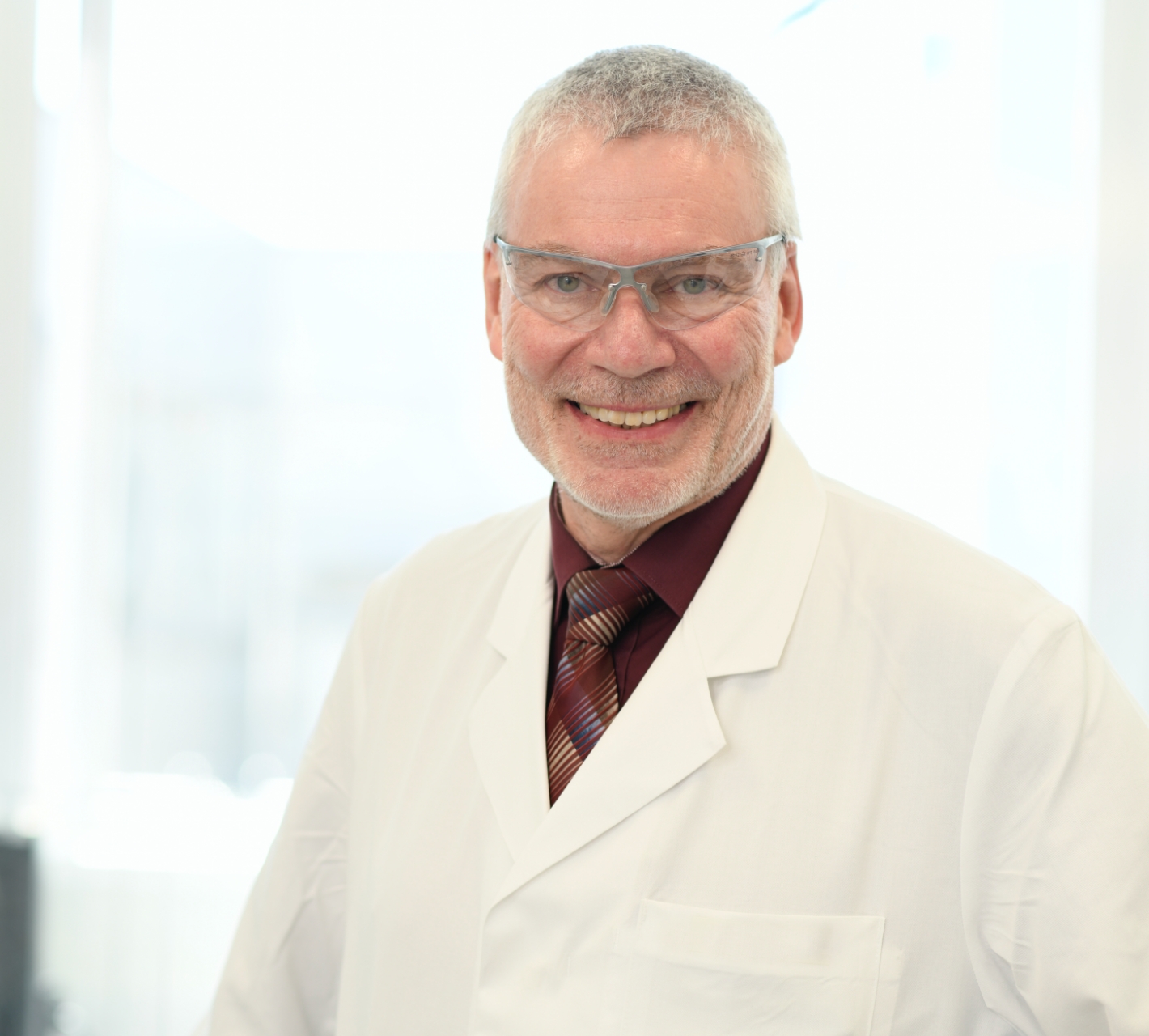

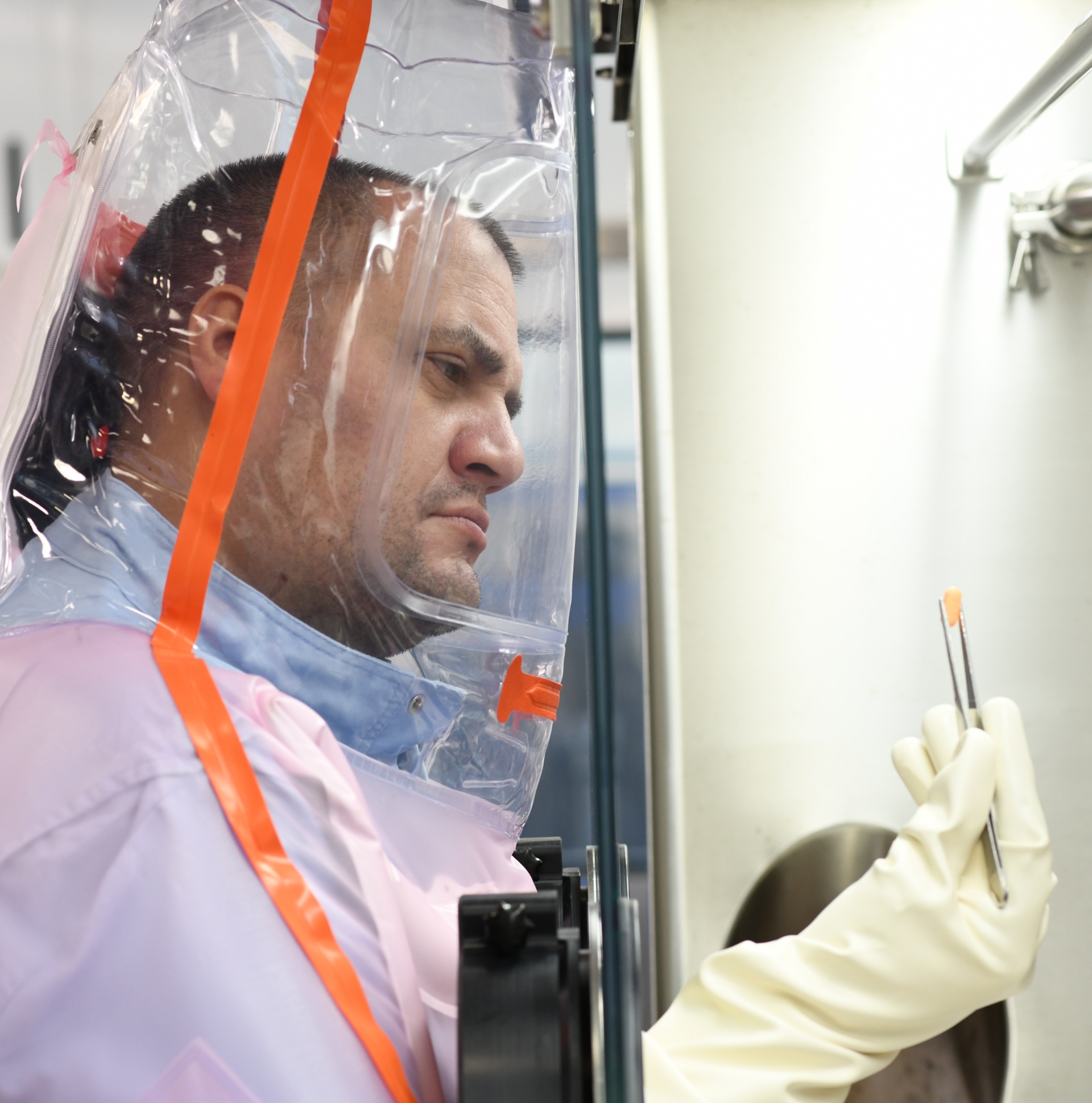

Dr. Gerhard Nössner, Chemical Process Development

The right chemistry is key.

It goes without saying that employee safety and environmental protection are our top priorities.

Dr. Gerhard Nössner, Chemical Process Development

We offer a wide range of research and development services for active pharmaceutical ingredients.

We have a wealth of experience in synthesis.

We are well equipped for analytics, from standard methods through to NMR spectroscopy, mass

spectrometry and trace analysis.

In addition to traditional organic reactions,

we also use modern synthesis methods.

And we know our way around “green chemistry”.

It goes without saying that employee safety and environmental protection are our top priorities.

Dr. Gerhard Nössner, Chemical Process Development

This means being open about our limitations before we begin the project and offering solutions where possible.

Dr. Axel Huwe, Chemical Process Development

Developing and optimizing

chemical processes pursuant to

current guidelines, e.g. ICH Q11, M7, etc.

Characterizing final products

and intermediate steps in

API synthesis. Identifying impurities

including fate-of-impurity (FoI) studies

Feasibility studies:

Developing innovative and

eco-friendly processes

Optimizing volume

yields and throughput times

Supporting direct API

technology transfer

from customers to our

production facilities

Developing crystallizations

to adjust particle

size distributions (PSD)

Investigating crystallization

behavior, solubility

and polymorphism

(Crystal16(R), XRPD, SEM,

microscopy)

This expertise allows us to be independent, something which makes us truly proud.

Dr. Thomas Lehmann, Analytical Development

Design of

experiments

Simulation software

for technical

processes

PROCESS ANALYTICAL

TECHNOLOGY

(ReactIR(R), PVM(R),

Lasentec(R)

Reaction calorimetry,

RADEX (5 g)

and DSC (10 mg)

Laboratory

automation

– Mettler

– Optimax

– Labmax

– Systag

– Flexilab

MODERN

ANALYSIS METHODS

– GC-MS

– LC-MS (high resolution)

– NMR

– IR

– XRPD

– REM

We always check if green solvents can be used in our development steps.

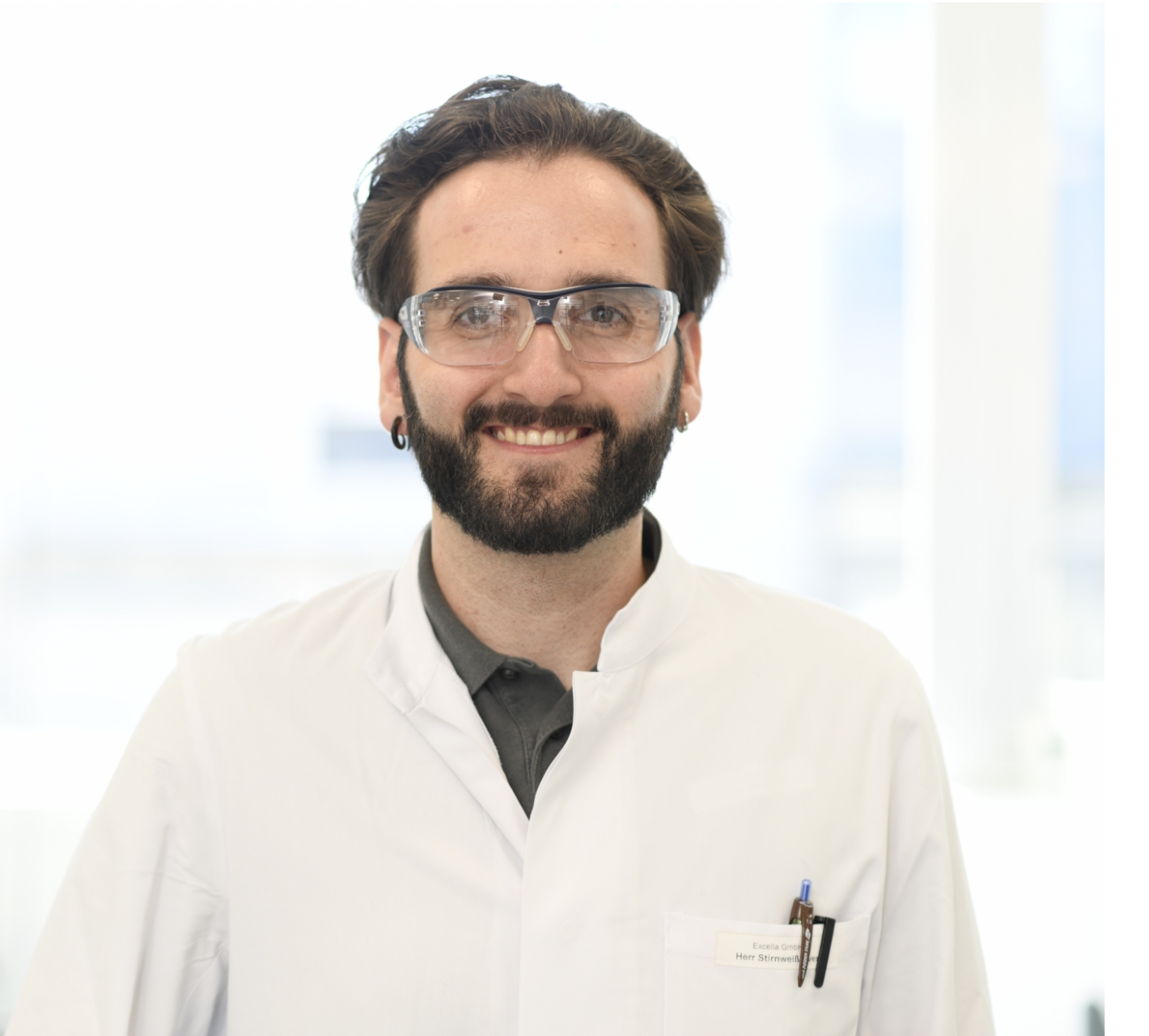

Sven Stirnweiß, Process Development

We also have constant access to original citations.

This helps us to get creative when developing syntheses.

Dr. Carsten Jagusch, Process Development

PRODUCING ACTIVE PHARMACEUTICAL INGREDIENTS

We produce highly potent active pharmaceutical ingredients – from

5 kg to 20 tons.

DEVELOPMENT OF TABLETS AND CAPSULES IN THE HIGH POTENT RANGE

We develop and manufacture products in line with international standards.

ENVIRONMENTAL PROTECTION, OCCUPATIONAL SAFETY AND HEALTH

This is how we protect our colleagues and our environment.